Mining, or rather the extraction of metal and minerals, and textile production are some of the oldest manufacturing processes organised on the basis of the division of labour that provide people with a wide range of different items that are used in large quantities both for individual and social purposes.

Woven fabric is not only used for making clothes, it plays an important role in many other contexts, for example in the manufacturing process of containers for transport and storage of goods or for producing the equipment needed for ships.

Metal that was smelted from ore is needed for the production of weapons and tools; moreover, it is needed for construction and for minting coins.

And the minerals extracted during the mining process can be used as preservatives and indispensable food additives (salt), on the one hand, and as extremely efficient fossil fuels (coal), on the other hand. The fact that these goods are so manifold and important for our lives is the reason why the processes needed to produce them have always been of crucial social importance.

A Complex Process Leads to a High Degree of Differentiation

The processes involved in these industries are very complex. That’s why they soon required strong differentiation and a high degree of specialization. Regarding the organisation of the work, various tasks required for the production were divided and put in a hierarchical order. Since the high Middle Ages, this division of functional levels had also been reflected in the social organisation of the workers: miners and smelters came together in miners’ guilds, and textile workers (combers, spinners, dyers, weavers etc.) were organised in various guilds. All these bodies developed their own order and own traditions; and they ultimately played an important role in the transition to the modern era as they were also political associations.

Silver for Germany’s Coins

In Germany, the extremely profitable business of mining of silver – the most important metal for coin production – had been carried out on a large scale since the Middle Ages in the Upper Harz, which mainly was part of the Duchy of Brunswick-Lüneburg, and in the Electorate of Saxony.

However, at the beginning of the 15th century, the deposits located in the top layers of the ground, which were easier to mine, were almost completely exhausted. As a result, the shafts had to be extended further into the earth and new tunnels had to be built on levels that were difficult to access. This caused several problems regarding the removal of yield and overburden and in terms of ventilation and drainage. These problems could only be solved by innovative technical solutions.

Engineering and Mining: A Successful Partnership

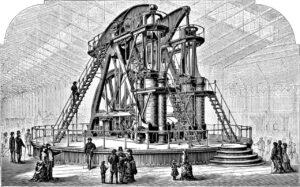

From the 17th century onwards, mining (as military technology did before) became one of the most important sources of innovation for mechanical science and the art of engineering. Complex mechanical designs gradually improved the efficiency of conveyors and pumping stations. Of course, the machines still depended on external energy supply. First, they relied solely on manpower, later horses were used too. Finally, water power enabled them to operate larger systems that needed way more energy. However, the supply and discharge of water above and below the ground called for an enormous effort in terms of construction.

Mining Issues: Testimonies to a Ruler’s Wealth

For territories that had both their own source of precious metals and the right to issue money, it had become customary to use some of the net proceeds from the mines to mint special coins or even large showpieces featuring an indication as to where the metal came from.

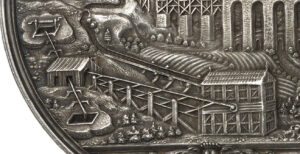

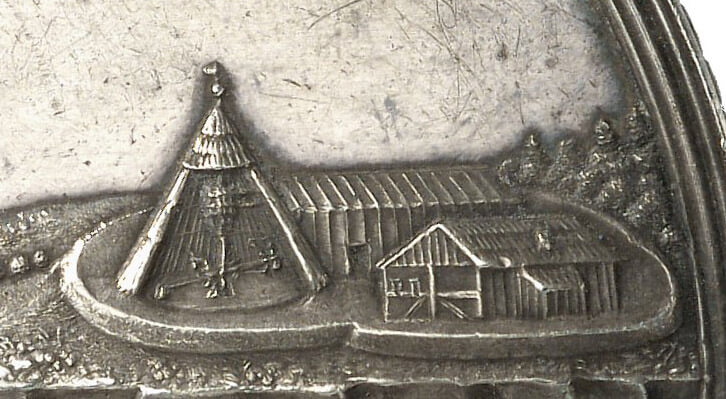

This large medal weighing 8 reichstalers (ca. 233 g) minted in 1690 in Freiberg, Electorate of Saxony, is such a mining issue. It celebrates the (temporary) start of silver mining in the mines of St Anna and Altvater near Rothenfurt in the Ore Mountains, which could only be put into operation thanks to state-of-the-art mining equipment. To operate the great “water art” for discharging all the seepage water from the mine, which was up to 260 meters deep, the Münzbach stream, which rose on the other side of the mine, had to be diverted and brought to the mines via an aqueduct. A huge water wheel located underground was put in motion by the stream, which would then lift the mine water in containers to a point just below the level of the wheelhouse, where it flew away together with the process water via the Anna tunnel.

The obverse of the issue depicts a view of the mine’s above-ground facilities with the not quite finished aqueduct above the deep hollow. On the left side, above the aqueduct, there are some buildings arranged around a cone-shaped conveyor tower. Below the level of the aqueduct, the water goes through a channel to a two-story building at the bottom of the picture, which apparently houses a water wheel installed above ground. In front of this building, a construction made of rods for reversal of motion leads to a smaller house further to the left. On the left, there is a man-powered engine with two cranks over an open shaft, which is connected by a rod to the small house and to another shaft opening. In the background are wooded hills with fields and other mine buildings.

In the exergue, there is the name “ST. ANNA” and in an ornamental cartouche in the sky the phrase “WAS MENSCHENHAND DURCH GOTT THUN KAN DAS SIEHT MAN HIER MIT WUNDER AN” (Here you can marvel at what man can do through God).

The reverse shows a vertical plan of the mine and the underground facilities. Above ground, we can see human- and horse-powered engines. On the right is a shaft in which a barrel is pulled up by means of a chain. In the middle, there’s the main shaft with ladders for entry and exit, as well as the wheelhouse and the pumping station. Miners are working in tunnels that are located on different levels and connected to the main shaft. On the top, a hand rises from the clouds holding a coin with the crossed swords of the coat of arms of the Electorate of Saxony.

The rim of the medal features the inscription “*ZUM MEISNER ROTHENFURTH, HAT AUF ST. ANNEN SCHACHT *BEY FREYBERG, GOTT UND FLEIS, UNS DIESE AUSBEUT BRACHT. A°. 1690”.

Mankind Celebrates Itself as the Master of Nature

The depiction, a work by the medallist Martin Omeis from the Electorate of Saxony, and its obvious preference for technical details, points in the same direction as the proud motto on the obverse of the coin: it celebrates that man masters and transforms nature. The medal is thus an expression of a completely new world view. The world is considered an ensemble of effects that can be calculated and therefore controlled by man. The same opinion was advocated by the rationalist philosophers of the Enlightenment such as Isaac Newton in England, Gottfried Wilhelm Leibniz in Germany and Jaques Leclerc du Buffon in France, and they were all very interested in the practical use and technical implementation of their theories. This resulted in the primacy of natural sciences (which continues to this day) and a tremendous development boost in engineering.

Soon after the beginning of the 18th century, it was discovered in England that steam power could be used to drive larger machines. In contrast to the natural energy sources used until then, such as water and wind, steam power was independent of other factors and constantly produced energy. The field where this discovery was first used on a large scale was mining, but thanks to the development of steam-powered spinning machines and mechanical looms, it was soon used in the textile industry too. And when the first roadworthy locomotive was built, the entire traffic and transportation system changed. This was the prelude to the Industrial Revolution that was to spread throughout Europe in the course of the 19th century and bring about lasting changes in our society.

Continue Reading (in German)

- Paulinyi / U. Troitzsch, Propyläen-Technikgeschichte Vol. III, Ulm 1997

- K. Müseler, Bergbaugepräge, dargestellt auf Grund der Sammlung der Preussag AG, Vol. I+II, Hannover 1983

You can learn more about the subject of mining issues in this film, which presents the coins of the Preussag AG.

Find out more about the author of this article, Wilhelm Müseler, in our Who’s who.