by Ursula Kampmann

September 12, 2013 – Did you know that Germany is number one with regard to coin minting? No, it’s not because Germany has so many more Mints than most other countries but because almost every Mint actually uses German technology. Many small as well as big highly-specialized companies produce the machines necessary to manufacture coins. One of the major ‘global players’ is the Schuler Group with headquarters located in Göppingen, and not just since yesterday.

A founder at work. Detail from the original Schuler company building. Photograph: UK.

When Gustav Buschick and Theodor Choulant visited the machine works of Louis Schuler in Göppingen in April 1905, they saw as many as 30 minting machines to be delivered to China.

Company founder: Louis Schuler (1814-1890). Photograph: UK.

At that time, Schuler was an established company already. It had been founded by Louis Schuler (1814-1890) in 1839. He visited the famous Great Exhibition, the very first World’s Fair, in London in 1851. There he could see how metal was processed, i.e. not time-consumingly by hand, but with the aid of huge presses. Schuler wanted to do the same in Germany, and thus started to construct machine tools for sheet metal processing in 1852. Since around 1870, Schuler has likewise been producing minting machines. That, however, constituted only a small part of the business.

The next generation: Louis Schuler (1840-1913). Photograph: UK.

The innovative company focused exclusively on metal forming, even where large work-pieces were concerned. In 1879, it designed the world’s first eccentric and drawing presses with mechanical drive.

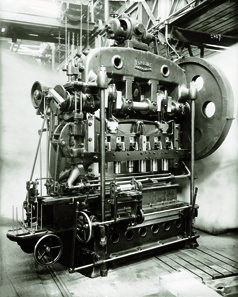

Transfer press, introduced by Schuler at the Paris International Exposition in Paris in 1900. Photograph: Schuler AG.

Schuler then became one of the exhibiting companies at the Paris International Exposition in 1900, presenting its transfer press.

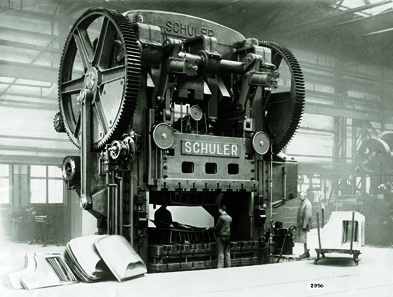

Opel applied a Schuler press in 1928, for the production of auto body panels. Photograph: Schuler AG.

The company’s blooming was linked to the motor industry. Accurate machines were needed for the production of large-sized pieces in one work step. As early as 1924, at a time when Mercedes and Benz were still two separates manufacturers, Schuler delivered the first auto body panel presses for mass production.

Schuler Group headquarters in Göppingen. Photograph: Schuler AG.

Today Schuler has roughly 5,500 employees, including 800 engineers, in Europe, the USA, in Mexico, Brazil, India, China, Thailand and Russia. Old-school as that may appear, Schuler considers its highly trained personnel the most important capital. It comes as no surprise then that many employees spend not only their entire occupational life with Schuler but are second- or even third- and fourth-generation professionals. Only recently, Schuler has been certified Top Employee 2013.

New apprentices in Mexico. Photograph: Schuler AG.

Schuler takes a leading part in a vocational education program in Mexico based on the German apprenticeship model to fit future professionals for the Mexican metal industry.

Visitors are greeted by a Schuler press at the parking area. Photograph: UK.

It was a hot day when I had the pleasure of visiting Schuler Group on behalf of CoinsWeekly.

Mr. Dieter Merkle, Managing Director of Business Unit Highspeed (of which more about later) gave me an all-day tour around the hallowed hall of Schuler’s.

Schuler, anywhere you look. Photograph: UK.

First of all, I got lost. The area is vast. All buildings you can see belong to Schuler.

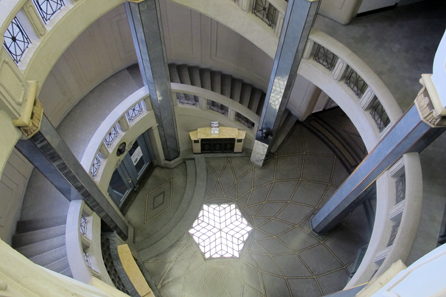

A view inside the headquarters’ monumental staircase. Photograph: Schuler AG.

It took me less than half an hour to find the right entrance where Mr. Merkle welcomed me. The following two hours were a lesson about minting technology since Schuler produces nearly everything needed to turn a metal coil into coins.

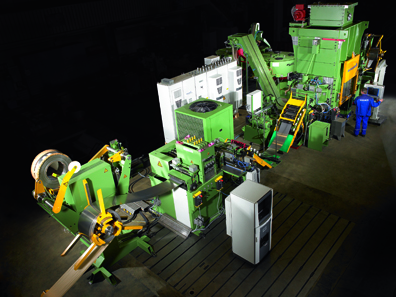

Schuler Blankmaster SAK. Photograph: Schuler AG.

From lines for the production of blanks…

RS 50. Photograph: Schuler AG.

… and machines for edge rimming…

MRH 150 with acoustic protection system. Photograph: Schuler AG.

…to minting presses for every purpose. There are both horizontal and vertical presses, i.e. the round blank is placed between the coining punches horizontally (horizontal coin minting press) or vertically (vertical coin minting press). The horizontal coin minting press is used only for round coins and achieves an output of 14 pieces per second. Over the course of a shift, that makes a coin output of more than 300,000! The vertically constructed minting press, in contrast, is suited likewise for non-round coins as well as bi-metal and tri-metal coins.

MRV 150 Ringmaster. Photograph: Schuler AG.

And the machine for the production of ring and core is likewise available for purchase at Schuler.

Actually, in case of necessity Schuler also provides turn-key coin minting facilities. A case in point is the Uzbekistan Mint: in cooperation with its business partners, Schuler supplied an entire Mint and trained the new employees.

A view inside the foundry. Photograph: Schuler AG.

That takes us from theory right into practice, hence to the giant production halls. Unfortunately, we weren’t allowed to see the foundry. That would have taken a special license and suitable protective clothing.

A view inside the production line. Photograph: UK.

The heart of machinery construction is a huge hall where the big presses are mounted. There are no minting machines here for they have their own section. Basically, this production line is nothing else than an assembly conveyer. The machine is assembled bit by bit at different successive workstations. The yellow bars underneath the ceiling are simply cat heads that facilitate transport of the heavy parts.

A truck can drive directly into the hall for delivery. Photograph: UK.

The size of this hall becomes apparent when looking at a truck driving comfortably through for collecting the machines. The minting presses are mounted in a gigantic adjoining room. This is where the manufacturing of the high speed presses is located, to which not only the coin minting presses belong but also the presses required for the production of aerosol cans or tubes. All of them make mass products. While the coin minting presses stamp an image into a blank, beverage cans are manufactured from a slug (‘Butzen’ in German) in a quick and effective way. That is a piece of aluminium – almost like an extra-large blank – which is formed between die and punch in a backward impact extrusion process.

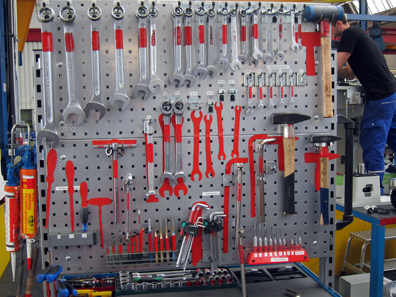

Good old-fashioned handicraft. Photograph: UK.

A major part of the secret of Schuler’s success in producing these high-precision presses is due to good old-fashioned handicraft, executed with meticulous care and passion for detail.

Cleanliness is next to goodliness. Photograph: UK.

The right tool for every procedure is near at hand at the working place.

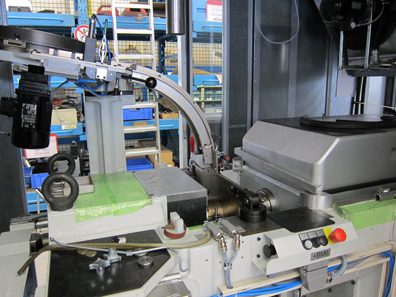

Blank supply for a horizontal coin minting machine. Photograph: UK.

Many of the things hidden once the machine is closed can be seen in their rough state, like the blankfeeding for the horizontal coin minting. The blank is placed almost vertically between the punches which are positioned not above and below, but on the right and the left-hand side. The decisive factor is that, thanks to its weight and earth’s gravitational pull, the blank drops quickly to the actual minting place in a way that couldn’t be achieved by the vertical procedure where it must be pushed in the right direction mechanically. This principle allowed the coin output to increase significantly.

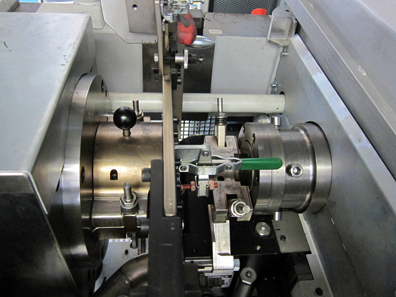

The heart of the horizontal minting. Photograph: UK.

And this is the heart of the horizontal coin minting. The coin is minted between these two cylinders.

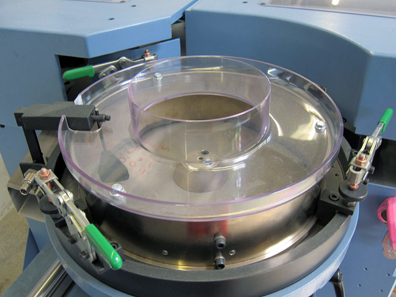

This is going to be an edge rimming machine. Photograph: UK.

Schuler likewise produces machines that are used to give the coin edges a layout of their own.

A whole series of edge rimming machines. Photograph: UK.

Some essential parts, like wires and electrics, are still missing here.

Schuler tokens. Photograph: UK.

It goes without saying that Schuler repeatedly tests the sophisticated minting methods that its presses make possible.

Part of the daily routine in Göppingen: Schuler presses. Photograph: UK.

What becomes apparent, no matter which employee of Schuler you are talking to, is the incredible pride about what Schuler embodies. The name stands for permanent checking and improvement of its own machines. The ambition of 800 engineers is to rethink what was already known and to cater for the technical needs of the future. Rare as bi-metal was prior to the introduction of the euro it has become well-established in mass-production. And Schuler has the next move in the fight against counterfeiters already in mind: tri-metal coins that have a non-round core with specifically designed edges. Whatever the plans, Schuler provides the right machines for it, before the governments have decided on the new coins.

If you want to learn more about Schuler, there is plenty information available on the internet.

You can buy Schuler shares.

This is a list of all of Schuler’s plant locations.

If you are looking for a new job, Schuler is always looking for employees.

Would you like to see Schuler’s coin minting machines for yourself? If so, please click here.

Schuler has its own channel on YouTube.

The German weekly business magazine Wirtschaftswoche reported on a record turnover that Schuler not only anticipated but actually realized in October 2012.

And of course you can follow Schuler at Facebook.