Material of the owls of Athens

But one day, one noon, I believed I had found it. I was at Sounion all by myself; the summerly sun was burning; the wounded pines dripped resin, and the air was filled with scent; a cicada sat on my shoulder and for some time we wandered together. I smelt like a pine-tree; I had become a pine.

View at the Temple of Poseidon at Cape Sounion.

And suddenly, as I was coming out of the pine wood, I saw the white columns of the Temple of Poseidon, and between them, glittering dark blue, the sacred sea. I trembled, I stopped. That is beauty, I thought by myself, the wingless Victory, the pinnacle of joy, man cannot reach higher than this. That is Greece.

Nikos Kazantzakis (1883-1957), from “Im Zauber der griechischen Landschaft“

Nikos Kazantzakis, author of Alexis Sorbas, would be quite astonished if he had not walked at Cape Sounion at the beginning of the last century but more than 2000 years ago, in the middle of the 5th cent. B. C. No scent of pines would have touched his nose, but a bitter smoke would have polluted the air instead. The Sounion area was renowned for its unhealthy climate. The air was filled with wads of smoke, the fire of the kilns lighted the night, far too many people were living, densely packed, in the area of the Laurion mines, between Cape Sounion and the port city Thorikos. An industrial area was located there which must have been very much like the Ruhr Area in the late 19th century in regard to dirt and environmental pollution. It was inhabited by pale, filthy figures. They worked incredibly hard to bring to the surface the ore containing rocks as the basis material of the silver needed for the most famous coins in Antiquity, the owls of Athens.

Athens. Tetrachdrachm, c. 450 B. C. Head of the goddess Athena. Rev. owl r. Photograph MoneyMuseum Zurich.

The name of this mining area is connected with the Greek word „laura” (= narrow path, alley). In the narrower sense Laurion refers to the area of the “ancient mine tunnels” indicating the long history of mining.

The ruins of Thorikos.

As a matter of fact, near Thorikos there are traces pointing to silver mining in the 3rd mill. B. C. As we know from isotopic analysis, merchants brought objects made of Laurion silver to Thera, Crete and Egypt as early as Mycenaean times. Most possibly it was under Peisistratos in the 6th cent. B. C. that natural resources were exploited systematically. The Laurion mines were flourishing in the 5th cent. B. C., when Athens was at the peak of its power.

In those days, the Athenian people leased the single mines to entrepreneurs. We know that from the preserved lists that specify which mine was rented by whom. The speech of Demosthenes (384-322 B. C.) XXXVII, 22, even tells us how much the right of use of a mine was. The orator refers to a man called Pantainetos who rented the right of use of a mine for 90 mines, i.e.1.5 talents or 9000 drachmae. That contract was concluded for three years after which the people of Athens as well as Pantainetos were entitled to cancel the contract or extend it against payment of the lease price.

The leaseholders did not always work in their mines themselves. Often they resorted to an administrator who need not necessarily be a free citizen. The case of the Thracian slave Sosias has come down to us who the rich man Nikias bought for 1 talent, i.e. 6.000 drachmae. Quite a sum of money! It was more than 30 to 40 times the ordinary price of a slave. But Sosias was an expert in searching for and finding silver tunnels. Nikias delegated the management of all of his Lauron mines to him and supplied him with 1000 slaves working for him in the mines. Nikias regularly received a dividend from Sosias. He was allowed to keep all additional yields. Surely, that slave was an exception from the rule. Few slaves managed to climb the social ladder to become a free man, most of them died before having saved enough money to by manumission.

View to the Agrileza Valley perforated by countless shafts and tunnels.

More than 2000 ancient shafts and tunnels were found in the Laurion area measuring 2000 hectares.

Subterranean border pillar.

They sometimes lie close together, separated only by stone pillars ensuring the security of miners and clearly marking the individual mine quarters. These pillars had to have a fixed size. Any leaseholder removing such a pillar faced the death penalty. A lease committee made sure about that – not out of concern for the miners’ security but because these pillars were official border stones. Diogenes Laertios I, 57 reports how, around 330 B. C., the rich entrepreneur Diphilos indeed was executed after he had taken such a pillar.

View inside a shaft and, clearly visible, an outgoing tunnel.

Most mines consisted of a shaft, 25-55 metres deep with a diameter of 1,9:2 oder 1,3:1,9 metres, which the single tunnels went out from. These tunnels measured 0,6:0,9 metres with a maximum length of 30 to 40 metres. Extending such a tunnel for 10-12 cm took 10 hours, i.e. one work shift probably equalling the burning time of a miner’s lamp. Digging tools were hammer, chisel, pick, shovel and crowbar. Naturally, no man could endure the hard work for 10 long hours in a row. It is assumed today that in the Laurion tunnels the miners worked in teams: one man was extending the corridor by digging, and the other transported the rocks to the end of the tunnel; after some time they alternated. They worked the whole night long, in shifts, since of course any leaseholder was eager to get as much as he could out of his mine. By the way, around 1910, of all people it was experts of mining that called the working conditions in the Laurion mines hard but not unbearable.

After being mined and transported to the entrance of the tunnel, the ore containing rock had to be further conveyed. That task was undertaken by children who carried the stones in a leather pouch, carried with a strap on the shoulder, from the pit to the processing plant. Sometimes a simple winch made their tedious job a bit easier. If the tunnel was wide enough a bag filled with stones could be pulled upwards with such a winch. Right at the entrance there was the place for a first presorting. The waste material was dumped on a tip adjacent to the entrance.

The presence of children at the Laurion mines should not come as a big surprise. Until the 19th century, they were engaged in mining the rock here in these parts as well: after all, their slighter physique came in handy for this kind of work. Plus, there were many children at hand at Laurion. Not just the few free Athenian citizens who earned their living with the mines had families. Marriage was not prohibited for slaves either. On the contrary, it was appreciated. A family served as guarantee that the slave behaved and provided additional work force that was for the most part put to work in the processing plant.

Processing plant.

Those were situated in close proximity to the mines and apparently had a fixed size.

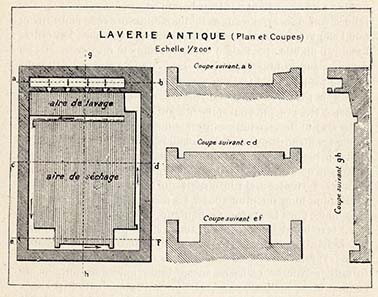

Schematic representation of a processing plant. From Aus E. Ardaillon, Les mines du Laurion dans l’Antiquité. Paris 1897.

They comprised of five picking tables where the waste material was sorted from the ore containing rock a second time. There, too, children, women and men who had grown old in the mines were put to work. Afterwards, the stones were crushed in mortars, likewise five in every operation.

Schematic representation of a stone crusher. From E. Ardaillon, Les mines du Laurion dans l’Antiquité. Paris 1897.

The next step of comminution took place at one of the three grinders where 4 to 6 workers crushed approximately 4 tons of ore containing rock per day. Again and again, the ore was sieved; at the end of this procedure, it had become the size of millet.

Cistern.

After that, a wet cleansing was undertaken. Each washing service had two facilities for that, with a slightly sloped washing surface, several leads with accumulation devices and a sedimentation basin plus a drying surface for the ore grains. There, the heavy metal parts were separated from the rock parts. The dry land made it necessary to bring the water needed from far away and to re-use it several times. It was stored in a masked cistern. Some of these testimonies of ancient mining technique, well preserved until the present day, could process more than 20 times the ongoing demand of a washing service.

Roughly 33 workers were employed in such an operation with the men working at the sedimentation basin being well-paid craftsmen. Most of them came from the slave market at Sounion, one of the biggest in Greece. Approximately 150 to 200 drachmae were paid there for an average worker. Youths were traded at considerably lower prices. They cost between 50 and 100 drachmae. For a highly qualified expert, one of those who were usually employed in the mines, roughly 250 to 300 drachmae had to be paid – the same as for the most beautiful slave girls.

Today it is assumed that the money a leaseholder of a processing plant had to invest in slaves constituted 40-50 % of his entire working capital. With mines, the percentage was even higher. There, slaves made up 80-90 % of the working capital. It comes as no surprise, then, that the Athenians soon began to think how they could avoid these high initial investments. They resorted to rented slaves as the Greek equivalent of today’s equity funds.

Anyone who wanted to earn his living with his own capital invested his money in one or more slaves which he leased. If they had not any particular qualification, the owner nevertheless received one obol a day; the day’s rent for a craftsman was considerably higher.

Interest was paid on the time off work, too, or in when a slave fell ill. Therefore, the profit from renting out slaves was secure and easy to calculate. The yield on an average slave with the cost price of 200 drachmae was 30 % which means that this investment paid itself off after roughly three years. Since in Classical times cash loans bore interest of only 12 % per year, the purchase of slaves paid off. The purchase was risk-free because the lender was personally liable if a slave was injured at work, died or fled.

The smelting, too, took place at the mining area. At Laurion, however, there are only minor traces left. There were only a few centrally situated furnaces. They sufficed to melt out the metal transported there from all the mines which was prepared in advance and consisted virtually only of lead and only little silver.

Most possibly these furnaces were “blast furnaces” similarly constructed like the ones we know from Spain. The necessary heat was generated by aerating with bellows. The toxic smoke dissipated into the air through a chimney. These furnaces were heated by wood and charcoal; in part, the wood had to be imported from far away.

Lead clamp to fix the column drums.

During this process not only silver was obtained but valuable lead as well which was used in the building industry. Countless water pipes and lead clamps were needed for the big rebuilding of Athens. Other “waste products” of the Laurion mining were mercury, cinnabar, red chalk and ochre.

Whether all silver for the coin production was transported to Athens or if there was a small mint in the mining area, remains a matter of dispute. The find of two crucibles made of lead oxide with a number of slots possibly for the production of planchets for drachmae may well indicate the presence of a mint at Laurion or Sounion.

As mentioned above, the Laurion mines flourished in the 5th cent. B. C. However, as soon as 413 B. C. the business was put to a temporary end by to the Spartan occupation of Dekeleia during the Peloponnesian War. In 404, when the war was over, the mining of silver was virtually non-existent anymore. Only a generation later, around 370, some entrepreneurs began to lease mines again and mostly managed older, closed down mines of the 5th cent. resulting in a economic boom of Laurion around 340. It was the competition of the gold and silver production of Macedonia and Thrace that cut the ground from under Laurion’s feet. Finally, when Alexander, called the Great, attained the Persian silver working in the regional mines became uneconomical. The silver price dropped in such a way that the yields from the mines did not cover the running costs anymore.

Another heyday began when the Romans defeated the Macedonians in 168 B. C. To prevent the Macedonians from rising again, Rom ordered all mines to be closed down. Hence, the Macedonian silver deliveries stopped and a market gap emerged in the Greek region which Athens was willing to fill. Cheap slaves, Roman capital and a new technique to extract silver from the already rendered scoria led to the resurgence of Laurion. Two slave upheavals could not stop that development. Scattered finds even date to Byzantine times.

Today’s visitor of Laurion can admire the testimonies of the ancient industrial culture seemingly just waiting to be put into operation again. The vast area is perforated with mines, and procession plants are lined up next to each other. Cicadas clitter, the scent of pines fills the air, and the noise of tourism so present at Sounion is way off. Truly, that is the real Greece. It is located far afield from the white marble ruins of the Parthenon in a lost valley that once provided the basis for Athens’ power.