It was on July 2nd, 1906, at three o’clock in the afternoon that the entire Swiss Federal Council came to visit the building of the new Mint in the Kirchenfeld district finished in May. Therewith, the Confederation officially took over its new money factory that had cost 1.179.000 Swiss Francs after all. Present-day Bernastraße was the chosen location. There, a private real estate company has offered the state premiers cheaper building ground than the city of Bern had at its disposal: the city set a price of 25 Swiss Francs per square meter building ground whereas the private company agreed to sell its ground for only 15 Francs.

Camp service of a Valais battalion on the Kirchenfeld. In the background on the left one can see the almost finished Mint with some scaffolds still in place. Photograph around 1906. Burgerbibliothek Bern (Negative Collection Stumpf).

The Confederation agreed on the building of a new Mint as early as 1893. The former Mint where the city of Bern had produced its coins from 1792 onward and which the new Federal State continued to use, had become too small. Paul Adrian (1858-1936), the then director of the Mint, and Theodor Gohl (1844-1910), appointed architect of the Directorate of the Federal Buildings, therefore traveled to Brussels and Paris to look for inspiration for a new and modern Mint.

Entrance to Swissmint from Bernastraße.

The architect Theodor Gohl specialized in state buildings. Almost all important Swiss central post offices were designed by him, like Fribourg, Chur, Basel and Lugano. In the Kirchenfeld district, two more buildings were his projects: the Swiss Federal Archives and the Topographical Survey of Switzerland.

View at the Swissmint courtyard with the entrance to the production wing.

Only one mint Theodor Gohl planned – and there he faced the challenge of combining a representative building and a fully functional factory. Gohl’s solution was to design a rather inornate industrial building surrounding a courtyard accessible through a central representative building with many nice artistic details.

Detail from the staircase of the central building of Swissmint: a cast-iron dragon decorates the lamp post in the centre of the spiral stairs.

In those days, the Federal Mint did not only mint but produced the planchets as well that were to become coins by minting. The first stage of the coin production was the alloying room where the correct alloy for the production of the Swiss coins was weighed. The metal was stored on the coalface – the base material outside in the courtyard, the noble metals behind steel-reinforced doors in the basement.

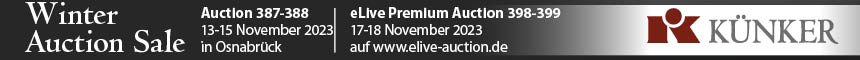

Look at the molten bath. Photograph 1908. Burgerbibliothek Bern (Photo album “Federal Coin”)

Afterwards, the metal was melted and cast in the so-called ingot moulds. A good idea of this process is given by a photograph from 1908 from a series that recorded the then major stages of the coin production. In the background, a worker squats beside a breeze oven with a swivelling spout. The hot metal was cast from this oven in a casting crucible and from the casting crucible in the moulds, the so-called ingot moulds placed in the foreground.

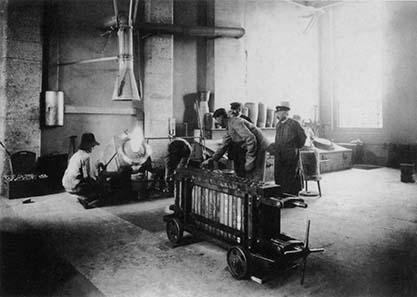

The metal strip is rolled out. Photograph 1908. Burgerbibliothek Bern (Photo album “Federal Coin”).

The produced elongated ingots were the basis for the metal strips by being passed through large rolling mills to the thickness required.

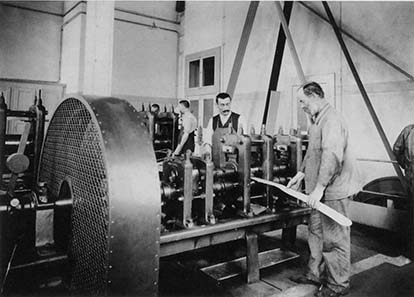

The planchets are stamped out. Photograph 1908. Burgerbibliothek Bern (Photo album “Federal Coin”).

From these metal strips the planchets were taken by using a hole punch. All pieces were mechanically weighed; those that did not conform to the correct weight were abraded, a “damage” that is called “adjust” in auction catalogues. After that, only the edge had to be raised. All that was left to do was to raise the edge. As a result of the different stages of the production the metal had become too hard to be minted; it had to be melted a second time to become malleable again.

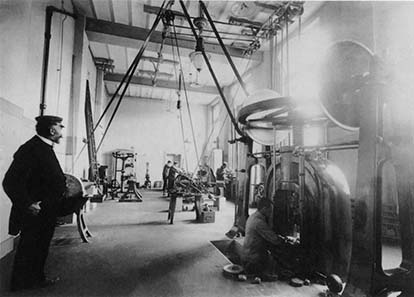

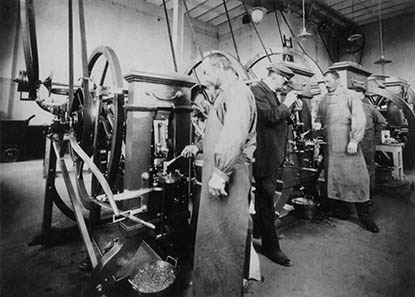

View inside the minting room: friction presses. Photograph 1908. Burgerbibliothek Bern (Photo album “Federal Coin”).

Two kinds of machines were used in Bern in 1908:

refriction presses, a derivative of the great beam

View inside the minting room: knuckle joint presses. Photograph 1908. Burgerbibliothek Bern (Photo album “Federal Coin”).

and knuckle joint presses. The fact that much more knuckle joint presses than refriction presses are to be seen here is characteristic for the range of a state mint that for the most part produces circulation coins. Whereas these can be made quickly and efficiently with the knuckle joint press, the especially high relief of medals calls for the refriction press which works more neatly and with more pressure. However, the process of minting with the refriction press was much more time consuming. The early knuckle joint presses, where the planchets had to inserted manually, achieved a minting rate of 80 to 100 pieces per minute (today’s rate: app. 600 pieces).

The coins are packed. Photograph 1908. Burgerbibliothek Bern (Photo album “Federal Coin”).

Packing the coins was very costly in terms of labour in those days. In the background on the left we see two men ascertaining the required number of coins by using a calculation board and putting the pieces in cups. Four women grouped around a table pack the numbered coins in scrolls of paper.

Of course, Swissmint does not use these machines for minting anymore. The building as well as the technology was completely overhauled during 1990 and 1992, the machines updated according to the state of the art. Today, Swissmint is ISO certified. 21 employees work here to produce the Swiss Circulation Coins and the Commemorative Coins – and to sell them.

Find more about Swissmint at http://www.swissmint.ch/