This article was brought to you by the B2B department of the Austrian Mint.

Let’s Start with a Little Terminology: What Is a Blank?

In the minting industry, a blank is defined as the ready shaped, well-prepared base material from which any coin is made. The blank – also called planchet or flan – is a round metal plate that is struck as a coin by means of minting tools. In principle, blanks can be made of any coinage material. In this article, we will focus on a special form of blanks – those that are used for gold bullion and gold commemorative coins.

Whereas most mints used to create their own blanks until well into the second half of the 20th century, in recent decades tasks have increasingly been distributed between mints and blank suppliers. Only a few mints still produce their own gold blanks. These are mostly mints of countries where a lot of gold is mined – but there is one exception: the Austrian Mint.

The Austrian Mint as Blank Producer

Although most coin collectors do not know it: if you buy a commemorative coin anywhere around the globe, there is a good chance that it contains a bit of cutting-edge technology from Austria, as the Austrian Mint is one of the world’s most successful producers of gold and silver blanks. About 60(!) nations mint their bullion and commemorative coins with blanks from the Austrian Mint – and that goes for both gold and silver issues.

DI Dr Manfred Matzinger, who has been the technical director of the Austrian Mint since 2012, gives several reasons for this: “Our entire production is tailored to the needs of our customers. We can meet every special request. And we provide customers with excellent advice, after all, not every complex blank upgrade is needed for every minting process. Our customers benefit from the minting experience that we at the Austrian Mint can provide thanks to our century-old tradition. All of our advisers, who exclusively serve the customer, are technically trained and have a direct connection to the production process, thus ensuring that the finished product is exactly what the customer needs – and it makes no difference whether it is a typical 1 ounce standard blank or a complete exception in terms of diameter or alloy. Since we can design every step of the blank production in-house, customers are free to choose which gold blank is the best for them.”

A Perfect Blank Is Made from Perfect Raw Material

Every chef knows it: the quality of the final product is directly linked to the quality of the ingredients. Thus, the quality of the gold used for gold blanks is crucial. The Austrian Mint only uses pure gold with a fineness of 0.9999 as raw material, then the required alloy is produced from it in-house. After all, the alloy with the highest fineness is not necessarily the best alloy for every coin. Especially regarding commemorative coins, other alloys offer many advantages.

Director DI Dr Manfred Matzinger comments: “We have many customers who order a very special alloy from us. Since we produce the alloy ourselves, there is no surcharge for small quantities of blanks with unusual alloys. This enables customers and collectors to save money: mints can calculate prices differently if the cost of the initial product is low. However, I would like to make one thing clear: even though it might save a little money, we don’t compromise when it comes to the environment, sustainability and fair working conditions in the refineries. For our blanks, we only use gold that comes from plants with BME certification.”

The BME, the German Association for Supply Chain Management, Procurement and Logistics, is a trade association of buyers operating primarily in Europe that helps its 9,750 members to make informed decisions when choosing raw materials. Among other thigs, the BME developed standards to ensure that BME certifications enable buyers to distinguish sustainably operating refineries from the bad apples of the industry.

Market Expertise to the Benefit of Everyone

Many investors recall with horror the situation in 2020, when the demand for gold coins exceeded the supply by far. Director DI comments: “In 2020, the Vienna Philharmonics was once again No. 1 on the global market. One of the reasons for this was the fact that we were able to deliver coins even in times of Covid. For three weeks, in fact, we were the only ones around the world who were still able to supply customers with bullion coins. And there was a good reason for it. We are a welcome business partner of many refineries. We negotiate with them on an equal footing and have long-term supply contracts. This is not only to the benefit of us and indirectly the buyers of the Vienna Philharmonic, mints around the globe also benefit from it because we were still able to supply them with gold blanks during the crisis. The fact that we cultivate long-standing business relations is also reflected in the conditions that these refineries grant us, and we then pass on these benefits in full to our customers, which can thus set more favourable prices for collectors.”

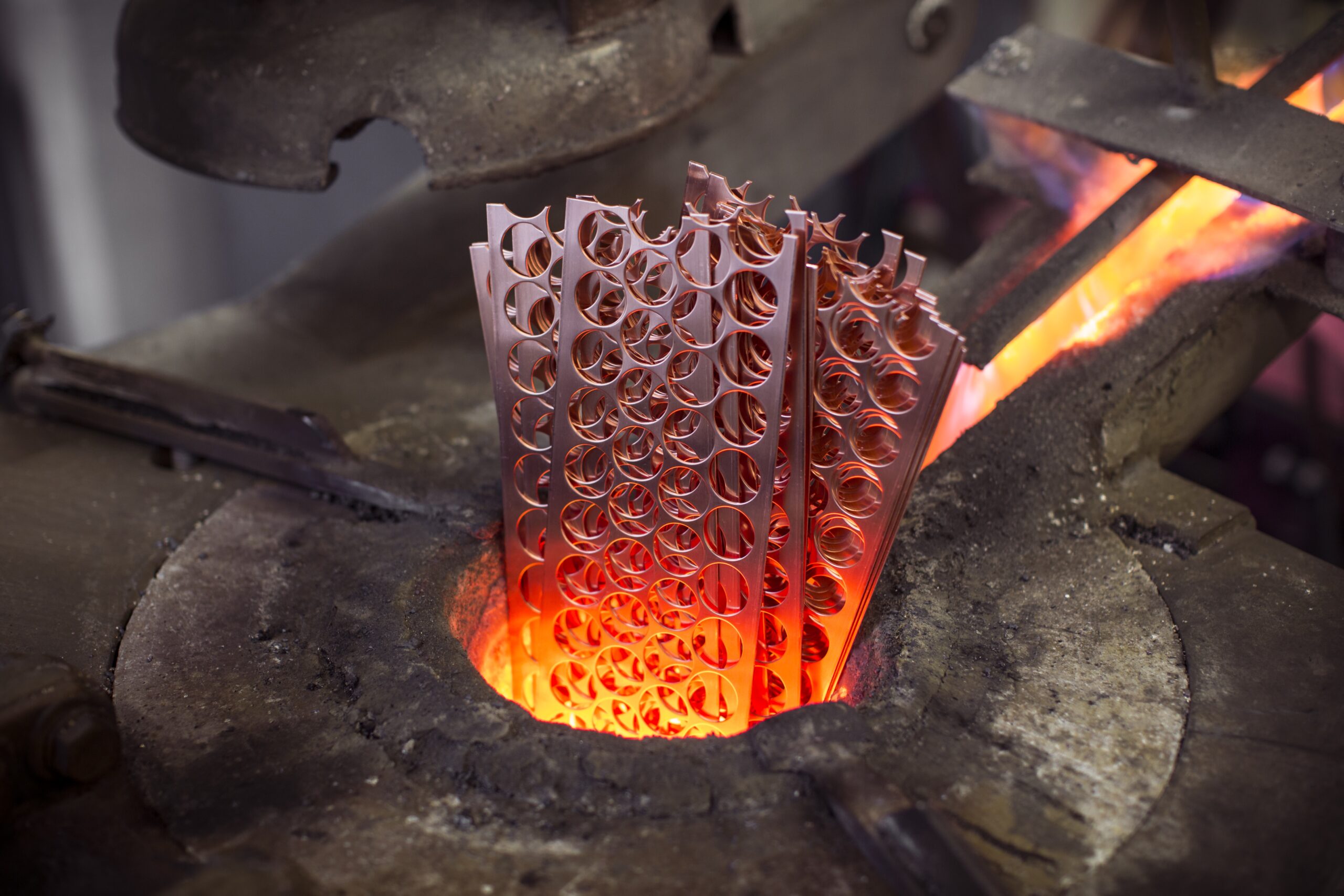

From Raw Material to Metal Strips

The refineries deliver gold in the form of ingots. They have a weight of 7.5 kg and perfectly fit into the smelting furnace, where any desired alloy can be produced. The in-house precious metal laboratory, which – by the way – is one of the world’s leading precious metal laboratories, ensures that the alloy perfectly meets the specifications.

As a first step, the laboratory carries out an initial inspection, and they do not only check the material purchased from other suppliers. VD DI comments: “When producing blanks, you are left with what is called webbing. We make sure that webbing of the right alloy is melted down in the smelting furnace and can be used as raw material again. Therefore, we do not have to return any of our gold to metal recycling plants.”

By the way, the exact melting temperature depends on the alloy. It is exactly calculated in order to save energy. The ultra-modern strip casting line of the Swiss manufacturer Wertli turns the liquid alloy into a metal strip. In this way, a unit of 7 litres of liquid gold becomes a strip of 140 kg. A technician of the in-house precious metal laboratory checks the composition of every single unit to assure the quality of the entire strip. When it is done, such a strip – also called coil – weighs up to 1.2 tons. VD DI comments: “To have an ideal process, we already adjust the width and height of the produced strip to the customer’s requirements at this step. In this way, every customer receives a product with ideal qualities that can be shaped at the lowest possible cost into a high-quality end product.”

Rolling / Milling

Another crucial step in the process of creating the perfect blank is rolling. The cast coil is then rolled to the right thickness – just like you would roll out cookie dough.

This task is performed by a state-of-the-art rolling mill from Bühler. By the way, the company actually produces rolls for bakery and pasta productions in addition to rolling mills for metal – although the technology is obviously somewhat different.

The first rolling has the purpose of making the coil thinner. This does not only make it wider and longer but also harder. However, this initial hardness is detrimental to creating coins with detailed motifs. Only a smooth blank enables you to achieve a high relief. For this reason, after rolling it for the first time, the coil is put into an annealing furnace where it is heated to about 600 degrees to become soft and easy to mint.

Then it goes straight back into the rolling mill: to produce a perfect blank, you need a perfect coil that almost does not deviate at all from the thickness specified before. VD DI states: “Rolling is our core competency. That’s why we purchased the world’s best rolling mill money can buy. After all, the rolling thickness is of key importance for the cost of the blank: If the coil is just a little too thin, you get an underweight blank that has to be sorted out. If the coil is a little too thick, the blank will be overweight and generates a loss of material. Our customers calculate costs on the basis of blanks that exactly meet the agreed specifications, by the way, also in terms of hardness. Every mint can choose from us how hard their blanks will be, enabling them to achieve an ideal end result.”

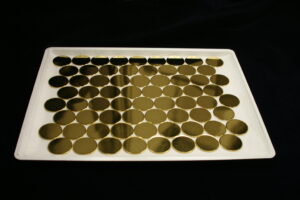

Producing Blanks with a Cookie Cutter

The next step is the blanking press. The coil, which had been rolled up before, is fed in the press and straightened again. A tool cuts the blanks from the metal strip. Director DI explains what is most important: “We discuss with our customers what exact tolerance – a figure in the 1/100 millimetre range – they desire in the cutting process. For the thing is: the fewer planchets we cut with one stroke, the higher the precision, but, of course, also the higher the tool wear and thus the cost. We produce the tools ourselves, but this decision has to be made by the customer. Just like he needs to decide whether he wants his planchets delivered with a certain edge design or not.”

A Customized Blank

In theory, the blank is now ready. At least after it has passed the meticulous in-house inspection that guarantees that it is of the perfect weight, the perfect diameter, the perfect alloy and the perfect thickness. Customers who want such a raw planchet can purchase it now, however, part of the further production process is typically also carried out by the Austrian Mint.

This includes, first of all, upsetting the edge: this creates a rim and every mint has their own specifications as to what this rim is supposed to look like. VD DI comments: “The Austrian Mint can produce any form of edge design. Everything we need is a precise drawing. Then we manufacture tools for the desired upsetting shape. And since this is done in-house, we are able to react very quickly if the customer wants to change something.”

For normal gold blanks, upsetting is done quickly and inexpensively by a machine. But there are also more elaborate ways to do it: for particularly exquisite commemorative issues, every blank is inserted by hand in order to protect it from any damage caused by touching other blanks. VD DI says: “These are obviously absolute high-end products, but this treatment makes the minting process easier. Of course, we also offer different finishing options for planchets for different quality requirements.”

Polishing

The machine used to polish the planchets is made by the Spaleck company and was acquired just one and a half years ago. In this way, the Austrian Mint does not only comply with all EU standards, but exceeds them by far. VD DI comments: “I have children, and I want to leave them a world where they can experience an intact nature. That’s why it’s important to me to work as sustainably as possible. We at the Austrian Mint don’t just want to create perfect blanks, we also want to do it in a way that does not harm our environment. Many of our customers appreciate that. After all, the price of a product is not the only important thing, customers also want to be sure their purchase is not detrimental to the environment. Traditionally, many chemicals are used for polishing, which can always be recycled thanks to the state-of-the-art technology used by this machine. Such environmentally friendly methods are used for every finishing process, whether we polish 70 kg of planchets in a single step with steel polishing balls or whether we process just 7 kg of planchets in a polishing drum.”

By the way, the time required for these two polishing methods varies greatly: while the standard method for 70 kg of planchets only takes 20 minutes, polishing them in a polishing drum takes up to 14 hours. VD DI: “That is the difference between a standard planchet and a high-end product designed to meet the highest requirements. The customer decides how much effort he wants. We adapt to their needs. Of course, this also applies to the smoothness of a blank. It can be adjusted according to the customer’s wishes. After all, quite rough blanks are not suitable for producing proof-like issues, which are very popular today, but blanks that are too smooth are difficult to mint. And at this point at the latest, our customers can take advantage of the fact that we ourselves are a mint with considerable experience in producing sophisticated issues. Our specialist sales staff are also technical advisors who can provide competent help if the customer is not sure what they need.”

Delivery

The fact that the customer is king is also reflected in the different delivery options. VD DI comments: “We can meet any customer requirement. We can even package blanks in a way that they can be fed directly into the minting press. No customer request is too complex for us.”

So there is a lot of technical know-how in every single gold coin – not just regarding the minting process but also the production of the blank.

You can find out more about the B2B department on the website of the Austrian Mint.

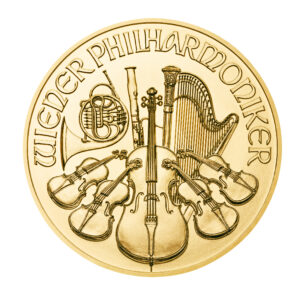

There you can also find out more about what’s probably the most famous product of the Austrian Mint, the Vienna Philharmonic.

By the way, there is an entire book dedicated to the Vienna Philharmonic (in German).

Here you can find some information about our interview partner, DI Dr Manfred Matzinger-Leopold.