translated by Annika Backe

May 19, 2016 – “Switzerland is precise. Even tunnel constructors allow themselves only a 0.00014% deviation.”

East tunnel of the Gotthard Base Tunnel. Photograph: Hannes Ortlieb / Wikipedia.

“Swiss women are straightforward. That is why they prefer the fastest connection.”

The tunnel aperture. Photograph: Cooper.ch / Wikipedia.

“Swiss people like to be punctual. That is why they love small short-cuts.”

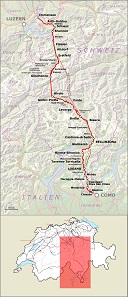

Map of the Gotthard Railway in Switzerland. By Pechristener on the basis of Open Street Map and SBB 2015.svg / Wikipedia.

“Switzerland follows its own path, therewith connecting the whole of Europe.”

With these and similar slogans, the Federal Office of Transport praises one of the major technical achievements of our century, the Gotthard Base Tunnel. And, indeed, every Swiss citizen – and most of the Swiss-by-choice, like me – are proud of what has come into being since construction work began in November 1999.

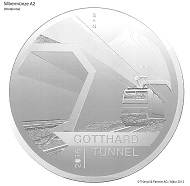

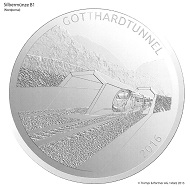

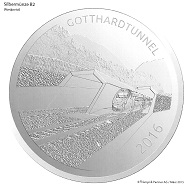

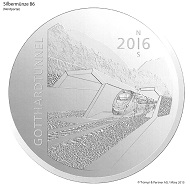

The occasion of the commemorative issue

With 57 kilometers in length, the new railway tunnel that will shorten the journey time between Zurich and Milan by about an hour is the world’s longest rail tunnel. It is built to shift goods transport from the roads to the railways, and most likely it will cost the Swiss population nearly 12 billion francs. It represents everything modern Switzerland is proud of: precision and Swiss engineering, environmental awareness and the willingness to assume responsibility in the heart of Europe. Scheduled for June 1, 2016, the opening of the Gotthard Base Tunnel will be a huge festivity for the general public that everyone witnessing – either on site or by watching it on television – will certainly remember for the rest of his or her life. The opening of the Gotthard Base Tunnel is something every mint dreams of: perfectly plannable history with a strong identification factor.

Of course, Swissmint has released commemorative coins on this occasion. Here, we would like to trace the production of these commemorative coins, from the initial idea to the finished product.

Letter to the Federal Department of Finance FDF, dating from September 19, 2014. © Swissmint.

Who authorizes the commemorative coin?

The idea to create a commemorative coin on the occasion of the opening of the Gotthard Base Tunnel is rather obvious. In Switzerland, however, it is not within the federal mint Swissmint’s competence to decide on the motifs of the commemorative coins. This is the responsibility of the Federal Department of Finance, hence, ultimately, of the member of the Swiss Federal Council who acts as head of the Department of Finance. Back then, this function was held by Eveline Widmer Schlumpf. Swissmint accordingly presents a selection of possible motifs to her or rather, since 2016, to her predecessor Ueli Maurer.

Contract for the design of the commemorative coin “Opening of the Gotthard Base Tunnel” from February 2, 2015. © Swissmint.

The sketch of the coin’s motifs

There were no arguments against this topic. Quickly and effectively, the approval was granted as early as September 24, 2014. The time had come to take the next step: an artist was searched and found who was then commissioned with the design of the coin: Fredy Trümpi, a renowned graphic artist, living at Binz not far from Zurich.

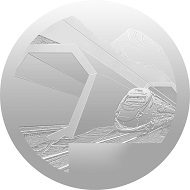

The first sketch – the basis for further work. © Swissmint.

How much thought has been put into such a sketch becomes apparent by a look at a statement of the artist dating from March 5, 2015. There, he emphasized that the effigy should make it clear that this is a modern railway tunnel and that all rolling stock complies with the latest technical standards.

An alternative sketch – this version was not given any further consideration. © Trümpi & Partner.

Fredy Trümpi inspected the site of the project. He not only had a look at the north and the south portal but also examined the surrounding landscape which he deemed quite important.

These sketches were by no means the only ones to choose from. © Trümpi & Partner.

However, he was willing to make some smaller concessions in this regard: “Minor warpings as a result of other angles are … tolerable. … The principle is: the greater the distance the fewer the details or, rather, the more simplified the depiction.”

Variants after the first reworking. © Trümpi & Partner.

Already after the first reworking, the individual sketches looked so similar that it almost becomes a search game when you try to detect the differences.

The final sketch. © Swissmint.

After another reworking, which mainly focused on the positioning and the design of the inscription, the final sketch was finished – it had taken less than two months.

Approval of the design, dating from March 25, 2015. © Swissmint.

The sketch had to be submitted for approval to the head of the Federal Department of Finance who has the final saying on all commemorative coins’ effigies.

Line drawing of the ultimate sketch. © Swissmint.

From the sketch to the die

In the next step, the two-dimensional graphic is converted to a three-dimensional coin. First of all, a line drawing is being made and the computer is being switched on.

The modification steps on the computer. © Swissmint.

Anyone who still believes the stylus to be the engraver’s most important tool has definitely missed the recent development in minting technology. By now, the computer has become almost as important. Yet nobody should think that today it takes less artistic and creative skill than in the past to convert a sketch to a three-dimensional model by use of a computer.

The model produced by a CNC milling machine – theoretically speaking, it is no longer required for the production process. © Swissmint.

Actually, it would be sufficient to create a 3D model with the computer. Yet, as an intermediate step, it provides an additional security to produce a synthetic model with a CNC milling machine.

Digital version of the old reduction machine. © Swissmint.

Being three-dimensional, this milled model mainly serves to check whether or not the result created on the screen indeed conforms to what the artist intended it to look like. Once everything is as it should be, the computer data are used without any further changes. If the milled model has to be modified, a three-dimensional scanner feeds the new data into the computer. The computer then reduces the effigy to coin size and mill it in a mild steel cylinder. This takes between 8 and 14 hours. The original die so created is called a reduction.

Size comparison: in the middle, you see a human hair whose diameter is only slightly smaller than the tip of the drill that converts the data to an effigy. © Swissmint.

The high level of detail of this work becomes apparent by a look through a microscope. The drill that is used to remove the metal has a diameter that is only slightly bigger than a human hair. If even more delicate structures were to be generated – as needed for micro-printing or some color effects, for example – laser engraving would be needed in this phase.

The unworked original die. © Swissmint.

This is how the original die is being made, as the basis for all future work.

Using a stylus, the engraver reworks the original die. © Swissmint.

At this point, good old manual work is required. No machine in the world can compete with an experienced engraver with his stylus when it comes to breathing life into a coining die.

The hardened die is used to produce the positive die. © Swissmint.

Now, it is time for a copying process to ensure that the reduction die is as rarely used as possible. Surely nobody likes to create a new reduction die, right in the middle of the production of a new emission, which might deviate from the previous die – and this would constitute the greatest meltdown imaginable. To avert this, the hardened die is used to create the original matrix …

The positive die is being made to create coining dies in a subsequent step. © Swissmint.

… which is then hardened and used to produce the positive die.

Polished coining blank. © Swissmint.

The next step requires a polished coining blank.

Lathe. © Swissmint.

It takes a lathe …

Grinding of the die. © Swissmint.

… and a grinding machine.

The press for the reproduction of the dies. © Swissmint.

A press that generates a high pressure – like this oil hydraulic press of Sack & Kiesselbach – takes the hardened positive die to convert a coining blank to a negative minting die. For the production of a commemorative coin made of silver (mintage: 5000 Proof and 30,000 Uncirculated) 15 to 18 pairs of minting dies, including a reserve, are being made.

Some minting dies are being hardened. © Swissmint.

This minting die likewise has to be hardened before it can be used for coining. Galvanic chromium-plating allows minting more coins from a die than would be possible without this additional hardening.

Finally: the minting die. © Swissmint.

Finally, the minting die is finished. On the other hand, it always takes a lot of minting dies since no die lasts forever. As soon as a die exhibits only the slightest trace of wear, it will be replaced.

Blanks and polishing agents are inserted into a kind of “blanks washing machine”. © Swissmint.

The minting dies are ready now, whereas the blanks are still missing. Swissmint purchases the required blanks, as most other mints do nowadays. Depending on whether the coins are to be minted in “normal” or “proof” qualities, the blanks require different kinds of preparation.

View inside a polishing drum. © Swissmint.

As a general rule, the higher the price for a product, the more time and effort are spent on the preparation of the relevant blanks. By use of polishing agents and cleaning fluid, the blanks are mechanically treated to the effect that all scratches or recesses are erased.

Blanks are prepared to be washed. © Swissmint.

Afterwards, the blanks are put individually in a kind of automatic dishwasher …

Wash tunnel for blanks. © Swissmint.

… where residues from the previous pickling and polishing are being removed.

A minting press of the Gräbener company. Photograph: UK.

The minting

Only now does the minting begin.

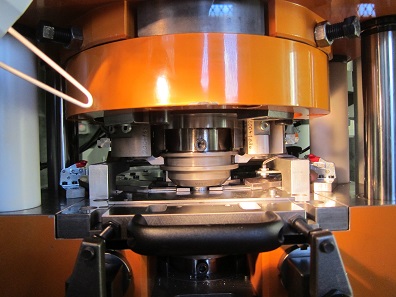

View inside the minting press. Photograph: UK.

The procedure is more or less still the same as it was more than 100 years ago, though it has become much faster. Into the machine the lower die had been inserted while the upper die comes from above. From the sides, the edge of the blank is being lettered.

Every “proof” coin is ejected from the press individually. © Swissmint.

While the coins in “normal” quality simply drop into a large container, the coins minted in “proof” quality are ejected from the press carefully and individually …

There is nothing like the human eye. © Swissmint.

… before Andreas Leu takes over, who checks thoroughly whether the production might not include a not quite perfect specimen.

Defective – these coins will never make it into circulation. Photograph: UK.

What he does not approve of is discarded.

A modern coin-wrapping machine. Photograph: UK.

The packing of commemorative coins

And we still have not reached the end of it. Now, the coins are being packed.

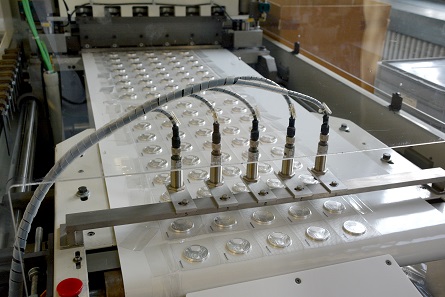

The coins are being aligned. © Swissmint.

An optical system checks whether or not the minted coins are in the right position. If they are not, the automaton will align them according to the desired model.

The “normal” quality coins are to be packed in plastic bubblewrap. © Swissmint.

The coins minted in “normal” quality are then wrapped into foil.

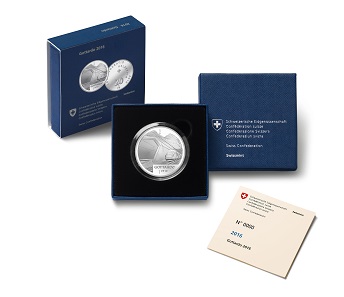

The commemorative coin in capsule and cardboard box. © Swissmint.

With a mintage of only 5,000 specimens, the coins minted in “proof” quality are hand-packed in coin capsules and cardboard boxes before being available to the customer.

It is only now that the coin can be distributed. Released on January 28, 2016, the silver coin commemorating the opening of the Gotthard Base Tunnel, in contrast, is already long out of stock. It will only be possible to acquire a few remaining coins on June 4 and 5, 2016, on the occasion of the festivities accompanying the Gotthard Base Tunnel’s opening. You better hurry.

By the way, shortly before the opening of the Tunnel, on May 26, 2016, there will be the first day of sale of the gold coin minted on the occasion of this major event in Switzerland. It features not the north but the south portal.

Please find the Swissmint website here.

There you may also find a more detailed description of how coins are being produced.

And this is the website on the opening of the Gotthard Base Tunnel.