translated by Annika Backe

“The San Francisco Mint is located at 155 Hermann Street, but only admits visitors on rare exception”, says the relevant entry in infallible Wikipedia. And you have to make intensive preparations indeed to visit the high-security wing of the San Francisco Mint.

San Francisco Mint. Photograph: Wikipedia / Seth Golub.

Name and personal data, like passport number and date of birth, are obtained per email already a week in advance. A detailed leaflet provides information as to what to do and, most of all, what not to do. And then the permission is given. For starters, we – my travel companion, Mary Lannin, Chair of the Citizens Coinage Advisory Committee of the United States Mint, who made this visit possible in the first place – drive around the Mint. The prominent location of the building is impressive. Like some kind of island, on its rock it seems to hover above the city. At first glance, the tall barbed wire fences have an intimidating effect. The guards, on the other hand, are polite while checking the car’s underside with mirrors to make sure that we do not smuggle any explosives onto the premises. Of course we don’t. And then the gate of the San Francisco New Mint is opening…

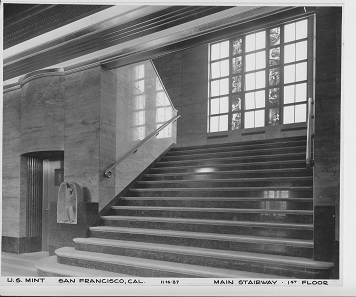

The foyer of the third Mint of San Francisco in a historical photograph. Photograph: National Archive, Gray Brechin has brought this picture to our attention.

On May 15, 1937 the New Mint of San Francisco was opened. The replacement of the old building was politically motivated. The 1922 stock market crash had triggered a severe economic crisis resulting in many people losing their jobs. For them, a comprehensive employment program was initiated under which, commissioned by the state, many infrastructure projects were undertaken. Altogether, 125,000 public buildings, 77,000 bridges and many other public sector buildings were completed during the New Deal. They include the New York airport La Guardia, the San Francisco Oakland Bay Bridge and, last but not least, the New Mint.

View onto a commemorative plaque in the foyer, stating the names of the politicians responsible for the building as well as the relevant architect. Photograph: UK.

It must have been a great time for architects, as becomes evident when you only consider how many buildings Gilbert Stanley Underwood (1890-1960) has designed, the architect of the New Mint. He was basically known for his more rustic style in which he built a dozen lodges for the National Parks. For the New Mint he preferred something that is called ‘Egyptian Revival Style’, and which may be viewed as a reflection of the stability of currency being manufactured inside the building. Serving as decoration of the building, 44 terracotta plaques feature coin types minted between 1790 and 1920.

A 1898 Spanish dollar, struck in the New Mint in 1949. From Stephen Album Rare Coins Auction 25 (2016), 2471.

In 1949, more than 10 million coins were minted in the San Francisco Mint, on behalf and in support of Chiang Kai-Shek. One-fifth consisted of Mexican pesos, backdated to 1898, which are easy to distinguish from the originals: The easiest way is to have a look at the date on the reverse. If the ‘M’ and the ‘O’ are at the same level, then the coins are the originals dating from 1898. If the ‘O’ is above the ‘M’, then it is a restrike from the San Francisco Mint.

Peter J. Haggerty, the then Superintendent of the Mint, examining a part of the production for China. Photograph: National Archives and Records Administration 296602.

Here, the then Superintendent of the San Francisco Mint checks a part of the production. The silver had been transported from China. Following the closure of the Shanghai Mint, the Chinese had sent 150 tons of silver and copper to have it coined into more than 3 million dollars and 6 million half dollars.

Staircase to the first floor with an elaborate glass window depicting the working steps involved in coin minting. Photograph: National Archive, Gray Brechin has brought this picture to our attention.

The New Mint, however, struck coins only until 1955 before production was stopped in San Francisco for cost-saving reasons. The magnificent building then housed a United States Mint’s buying office for noble metal where dentists and jewelers used to sell their old gold right into the 1970s.

A view into the minting room filled with Gräbener presses. Photograph: UK.

As of 1965, coins are being produced in San Francisco again. The first ones were circulation coins, intended to counter a coin shortage resulting from branch closures in the 1960s. Since the U.S. government resumed the issuing of commemorative coins in 1982, San Francisco is specialized in commemorative coins. Philadelphia and Denver mint the circulation coins while West Point produces the bullion.

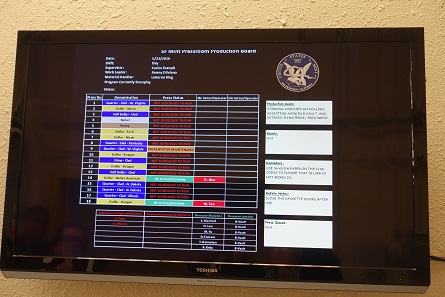

A computer monitor provides an overview of which coins are currently being manufactured. Photograph: UK.

San Francisco is very likely to be one of the world’s biggest mints for commemorative coins. By European standards, the number of coins struck is unbelievable. To mention only one example:

The ‘Everglades’ quarter of the 2014 ‘America the Beautiful’ series. Photograph: US-Mint.

Of the quarter with the ‘Everglades’ design, as part of the ‘America the Beautiful’ series, San Francisco minted 954,540 specimens of ‘Uncirculated’ quality, 784,467 Proof specimens, and 501,944 in silver, Proof, adding up to a total of 2.24 million pieces! Every year, five quarters are released. And these figures do not even involve the coins of this series that are intended for circulation, produced in Philadelphia and Denver, which amount to another 30 million (sic!). For comparison: Of the 10 euro German commemorative coin ‘Rotkäppchen’ (‘Little Red Riding Hood’) released on February 4, 2016 only 175,000 ‘Brilliant Uncirculated’ specimens were struck.

The Presidential dollar ‘Ronald Reagan’. Photograph: Wikipedia / Crashguy42.

Nobody will be surprised, therefore, to look at the 18 Gräbener presses standing in the minting room. Usually, they are pretty much working to capacity because not only quarters are being produced here but also a major part of the commemorative coins, including the Presidential dollars in Proof, of which San Francisco mints about one million every year.

William Tan helps me minting a coin in honor of Ronald Reagan. Photograph: Dawn Hoef / San Francisco Mint.

And watch out – among the one million coins is a Reagan dollar I have minted myself. Well, I have pushed the button of the minting machine myself. NGC or PCGS would have slabbed the specimen right away, therewith doubling its value…

A view inside the new PVD coating plant – the work is done under dust-free conditions. Photograph: UK.

Anyone who produces such large numbers of coins has a huge demand for coining dies. These are produced in Philadelphia where also the design is made. The final manufacture is done in San Francisco. It is necessary to prepare every single raw coining die prior to the minting. To that end, it is chrome-plated in a PVD coating plant.

In a dust-free room the coining dies are fed into the PVD coating plant. Needless to add, that usually it is not only one coining die that is being chrome-plated but a whole bunch. Photograph: Dawn Hoef / San Francisco Mint.

PVD stands for Physical Vapor Deposition. In simple terms, solid chrome is vaporized to the effect that the material hovers in infinitely small particles through the air before it is deposited on the die, forming an incredibly thin layer.

The computer makes it possible to determine exactly how thin the layer should be. Photograph: Dawn Hoef / San Francisco Mint.

This layer of chrome particles greatly increases the life-span of the die. And the coating is so thin that even the most delicate details of the die remain recognizable.

The polishing is also a fully automated process, as we are shown by Mrs. Monica Barnes. Photograph: UK.

The polishing is done in a fully automated process by a brushing and polishing machine from Switzerland.

Here you can see the different processing steps: non-chrome-plated – chrome-plated – polished – frosted. Photograph: Dawn Hoef / San Francisco Mint.

The chrome-plating and the polishing is followed up by the frosting, meaning the artificial roughening of the relief in order to create a bigger contrast to the mirrored fields.

The team of the die polishing department. Photograph: UK.

At this point, a very warmly thanks to the entire San Francisco Mint team – as representatives we show the team that is responsible for the die polishing. They all were so unbelievably friendly when they welcomed us and gave us a tour around the different departments.

Die polishing: the large furnaces in which the blanks are heated. Photograph: UK.

The San Francisco Mint does not manufacture the coining blanks in-house; in order to ensure that the end products exactly meet the collector’s wishes, however, the entire annealing is actually done in the Mint. The first step is the heating in huge furnaces. Its brittleness thus reduced, the material is then best prepared for the milling to take place.

Not just one Spaleck ‘coin washing machine’ but an entire room full of them. Photograph: UK.

Then the blanks are being milled, meaning that the lines that are to be seen on the edge later are being engraved. It is easy to imagine that the coining blanks no longer look pretty and smooth after this working step. And so a kind of ‘washing’ takes place. Of course, this is not done in a usual washing machine but in a complex plant designed specifically for this type of coin. During the polishing process not only stains but also minor blemishes are being removed.

The state-of-the-art packaging plant. Photograph: UK.

We have already seen how the coins are being minted. The only department we have not seen so far is the one where the commemorative coins are being put into their beautiful boxes and shrink-wrapped afterwards. In the San Francisco Mint, a modern packaging plant is in use which can pack as many as 150,000 a day for bullion and 20,000 lenses a day for 14 coin products.

The packaging still requires a lot of staff. Photograph: UK.

Nevertheless, when small quantities are concerned, it is much faster to pack them manually, as it takes a lot of time to adjust the packaging plant.

The tour is concluded in the magnificent lobby of the New Mint: (from left to right) Michael Levin, the most knowledgeable expert on the New Mint’s history, Ursula Kampmann, Mary Lannin, Chair of the Citizens Coinage Advisory Committee of the United States Mint, and David Jacobs, Superintendent of the San Francisco Mint, a function numismatists would refer to as mint master. Photograph: Dawn Hoef / San Francisco Mint.

Concluding the tour, Michael Levin led us through the magnificent lobby of the New Mint, a marvelous example of the architecture that was created at the time of the New Deal. We want to take this opportunity to thank all the people who made the visit possible: first of all, David Jacobs, Superintendent of the San Francisco Mint, who welcomed us in his office so kindly and gave us a tour around his Mint himself. The next person we are indebted to is Michael Levin, probably the most knowledgeable expert on the history of the Mints of San Francisco. For everything I wrote about the history of the mints, I relied on his leaflet. And, of course, there is Mary Lannin, keen coin collector herself and Chair of the Citizens Coinage Advisory Committee of the United States Mint.

Paul Lewis, Deputy Superintendent of the San Francisco Mint, and Ursula Kampmann talking to one of the employees. Photograph: Dawn Hoef / San Francisco Mint.

Not to forget Paul Lewis, Deputy Superintendent of the San Francisco Mint, who provided me with a wealth of detail.

By the way, if you wonder about the funny goggles: In the Mint, safety is given top priority. To that end, everyone gets steel caps for his shoes, plastic goggles to protect his eyes from flying sparks, as well as earplugs. Though perhaps not looking very good on you, it nevertheless can prevent injuries.

If you want to learn more about the minting process in the San Francisco Mint: Mike Unser has visited Mint in 2013 and gives a meticulous record of this visit in an eight part series. You will get detailed information on what the individual working steps in the San Francisco Mint actually involve.

Of course, the U.S. Mint maintains its own website for this Mint.

Perhaps even more impressive is its YouTube channel even though, to date, there is no video available that deals exclusively with San Francisco.

In 1936, an article was published that dealt with the new Mint’s security, stating that it would be equipped to cope with every incident imaginable. On this point, nothing has changed to this day.

CoinsWeekly already reported on the Old Mint of San Francisco.