by Ursula Kampmann

translated by Teresa Teklic

March 19, 2015 – Technicians from 21 companies, 18 talks thematically grouped into 9 units, and countless representatives of national mints. That was the Thursday afternoon programme at the World Money Fair.

Thomas Hogenkamp from Spaleck chaired one of the six sessions of three talks each. Photo: UK.

Dieter Merkle (Schuler Pressen) and Thomas Hogenkamp (Spaleck) once again put together a true tour de force showing off the minting industry’s latest innovations. Since each and every talk demanded undivided attention from its audience, the afternoon programme, which came to an end with a slight delay, left its listeners exhausted.

Here is a brief summary of all talks for those of you who could not attend the Technical Forum yourself.

Ross MacDiarmid, Royal Australian Mint: Silver Blanks

Ross MacDiarmid emphasised that choosing the cheapest supplier does not necessarily equal the lowest production costs possible. This becomes clear when looking at the real-life example of trying to reduce the rejects in silver commemoration coin production. Instead of letting the management base the decision where to purchase silver blanks solely on the price, the technical department went to considerable length to test which blanks produced the lowest number of faulty coins in combination with various chemical and mechanical pre-treatments. The result of this research was that impurity of the blanks’ surface before the minting process leads to unwanted spots on the minted coins. An even greater increase of rejects is generated by blanks which show actual surface blemishes upon their arrival at the mint.

Consequently the team put together a list of verifiable blank specifications. With the help of this catalogue the quality of suppliers’ products can be assessed in order to guarantee a minimum of faulty coin production for the Royal Australian Mint.

Dr Gerd Wagner, GmbH: hd-pro blanks

A radically new kind of blank was introduced to the public by Dr Wagner, CEO of Reischauer GmbH. His blanks have a particularly high ductility, which means they are particularly easy to shape, and they are profiled, which means they possess a profile that, for the first time in the history of minting, allows the producer to shape the blank according to how much metal is needed for the different parts of the coin’s profile.

To investigate the deformability of the hd-pro blanks, Reischauer used 12 g heavy 99 copper blanks. The high ductility blanks were three times as ductile as other comparable blanks. Thanks to the profiled blank form even its elevated parts were perfectly formed.

Although research is currently being conducted with copper blanks only, similar results with different materials are to be expected.

The new hd-pro blanks thus make it possible to significantly increase the minting profile while simultaneously reducing the pressure of the mint press by a third. This is beneficial as it reduces die abrasion as well as energy input for the minting.

Aziya Ibrayeva, Kazakhstan Mint: Study of impact of crystallization parameters (conditions) of the AgCu 92.5 alloy ingots on surface quality of proof quality coin blanks

Aziya Ibrayeva presented research undertaken at the Kazakhstan Mint. Experts at the mint had investigated the observation that seemingly identical blanks showed completely different results after minting. The answer to the riddle lies in the rapidity of the cooling process of alloys after being cast into the mold. Depending on the length of time of the cooling process, the material shaped into different crystalline structures. The copper distribution became uneven. This unevenness could not be reversed by subsequent heating or mechanical treatment.

The cooling process effects the minting results greatly as the study’s results show: ductility varied up to 5-6 %, the polish of the minted coins up to 10 %.

Stuart Wilson, The Royal Mint: Coin security: The technical challenges of designing and introducing a new, high value, high profile coin

Many mints are currently working on the introduction of new high value coins. Stuart Wilson shared some of the Royal Mint’s concerns and considerations on the topic with us. The major problem here is the cost-benefit ratio. How many security features do we need for coins? The more security features, the higher the production costs and the higher the rejection rate at vending machines. So each denomination requires careful consideration as to which security features should be implemented.

2014 National Baseball Hall of Fame commemorative coins. Source: Wikipedia. United States Government / Department of Treasury – United States Mint.

Ronald E. Harrigal, US-Mint: Manufacturing Curved Collector Coins in High Volume

Representatives of the US Mint shared some experiences that the mint had with the first concave collector coins in its history. The mint wanted to use their already existing equipment and use standard blanks as well as standard dies. Using digital relief analysis to pinpoint problematic spots was crucial in making this project possible. By systematically altering the design until the optimal solution was found it became possible to realize all objectives at once. The only downside was the shorter durability of the dies in comparison with those of other commemorative coin programmes.

Loic Pollet, Velec and Thabo Nikitseng, South Africa Mint: SA Mint Fully Automatic Packing Line

The volume of material that can be processed by mints today with the help of new machines is incredible. Take for instance the new fully automatic packing line acquired by the South African Mint in cooperation with Velec.

The idea behind this project was the wish to build a machine that runs 24/7 without relying on any form of human intervention. The new packing line is able to resolve jammings of any kind itself. It can count 6,500 coins per minute and is able to pack 5 million coins a day!

Markus Schlein / Sack & Kiesselbach, Enhanced Feeding Solutions in the Numismatic Coin Production Area

Markus Schlein talked about a recent development of Sack & Kiesselbach’s that was born out of a cooperation with the Berlin Mint department’s for commemorative coins. The innovation in question is an enhanced feeding solution which feeds ring and core separately into the press instead of using prefabricated bimetal blanks. The new technology yields the benefit of higher ductility and energy efficiency as well as longer durability of the coin dies. Besides it is considerably easier to polish ring and core separately. Plus, machine capacity is utilised more efficiently if assemblage and pressing are combined into one process. Of course this system proves most advantageous for minting commemorative coins; for the quick minting of circulation coins it is too time-consuming.

Hermann Schürer, Economa, New highspeed precision weight checker for blanks and coins

Hermann Schürrer alerted the audience to the fact that too much expensive material is wasted in bullion coin production due to the great weight tolerance. Economa’s new highspeed precision weight checker, which can check the weight of 50 coins a minute accurate to ten milligrams, provides a good solution. Weighing blanks before and not after minting could save a lot of money because blanks that exceed the required weight specification would not even enter the minting process but be melted down again.

Seven New Wonders. Poland’s first spherical coin. Photo: © Mint of Poland.

Siemowit Kalukiewicz, Mint of Poland – Most technically advanced 3Dimension coins

The Mint of Poland has taken the next step towards conquering the third dimension of the coin universe. After having successfully minted a cylinder and a pyramid, it has now added a globe to its collection. Difficulties began to show already in the design. For its generation with the ArtCAM software, the design had to be dissembled into 7 parts first.

Early test runs were done with copper, but it became clear very quickly that it would not be possible to mint a very deep relief. With reliefs of more than 0.2 mm depth, you run the risk of having the metal become stuck to the die.

Engraving the dies is in itself highly difficult and time-consuming: the process took 52 hours for one die only.

The spherical coin was minted at 600/ 650 kilonewton on a intermediate product by using a sexpartite die.

InfiniteFocusSL: Photo: © Alicona.

Alfred Gnadenberger, Austrian Mint, and Christian Janko, Alicona, Optical 3 D micro coordinate system for form and roughness measurement and its use in minting

According to Alfred Gnadenberger from the Austrian Mint, the system of optical 3 D measurement developed in cooperation with Alicona offers a number of advantages for minting. While the old system captured only individual measuring points, the new method generates a complete profile that can be saved and returned to for analysis of different aspects.

This way of metering was particularly useful to detect faults in the manufacturing process. Which parts of the die wear down first? Why do some dies break faster than others? Optical comparison of the metered dies quickly renders such problematic areas visible.

Further, metering can be a useful tool in the production of dies for replicas of already existing coins and for the quick metering of rimmed edge profiles.

Romain Waidelich, Miba Coating Group, Environmental and working safety aspects of the PVD coating technology vs. galvanic technology

Given the fact that regulations on galvanic technology with its use of aggressive chemicals are becoming increasingly strict, Romain Waidelich compared two methods of die coating: galvanic technology and PVD (physical vapour deposition).

He noticed that, as yet, there are hardly any safety regulations in place for the latter. PVD is easy to install and offers a wide array of possibilities with regard to the material used for coating. What is more, the average durability of dies can be extended by 20 % thanks to PVD coating. Still, it should be kept in mind that this coating method copies the dies’ features exactly so that pre-existing faults on dies cannot be filled and compensated.

Volker von der Heide, Oerlikon-Metaplas GmbH, The New PVD HI3-Technology – Latest Developments and Potential for Coining Dies.

Volker von der Heide went one step further by introducing a new machine from Oerlikon-Metaplas, the first machine able to execute all three different technological processes currently used in PVD coating. He then presented these three technologies – the APA Arc Technology, the Magnetron Sputter Technology, and the HiPIMS Sputtering Technology with their respective advantages and disadvantages.

Robert Newman und Timothy Buch, DELCAM – ArtCAM, Pushing the boundaries of visual security

Like every year DELCAM – ArtCAM presented the latest features implemented in their coin motif creation software. This time Newman and Buch focussed specifically on questions of using their technology – generating guilloches, microtexts, latent images, and many more – to improve coin security.

Mühlbauer’s CCI Edge Inspect. © Mühlbauer.

Ralf Freiberger, Mühlbauer, Coin edge inspection – how to integrate in automatic, high throughput processes

The method used by Mühlbauer machines for edge inspection without an additional working step is as brilliant as it is simple. Ralf Freiberger pointed out the weaknesses of traditional edge inspection which not only requires several shots but also tends to be slightly blurred around the edges. By using a ring-shaped reflector, the new Mühlbauer machines capture the front and back of the coin’s edge.

The method can test 3,000 coins per minute. Plus, the feature can be integrated into already existing machines.

Rhino – The new bank sorting machine from InduVis snd INEA. © Inea / InduVis.

Lutz Büker, InduVis und Simon Watterton, INEA, New solutions in the inspection of blanks

Yet another new machine which combines the expert knowledge of two specialist companies was presented by Lutz Büker and Simon Watterton. Inea specialises in wrapping machines, InduVis in high-quality sorting machines. The new blank sorting machine developed in cooperation is called Rhino and, according to its developers, had an ROI of two years, thanks to its advanced technology. The new technology is exceptionally easy to handle, reduces power consumption and the number of false rejects.

Up to 3,000 coins a minute – blanks, circulation coins (newly minted and circulated), commemorative coins, bullions, with a diameter between 9 and 40 mm –can be processed by Rhino.

Paolo Mascioli and Massimo Bersani, IPZS, Stress analysis of the working dies

The Italian Mint summarised the results of a comprehensive study in which differently manufactured dies were compared in stress analysis.

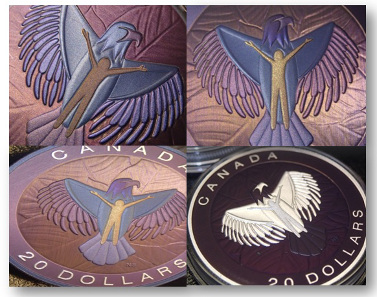

One of the Royal Canadian Mint’s first coloured coins produced by using nano technology. © Royal Canadian Mint.

Dr. Xianyao Li, Royal Canadian Mint, Nano technology for minting applications

Butterflies, began Dr Xianyao Li his talk, do not owe their brilliant colours to pigments of some kind or another, but to the surface structure of their wings. The Royal Canadian Mint has now succeeded in imitating nature’s nano effect in its coin design. Thanks to a specialised laser technique, precise shades of colours can be produced by varying the size, material, form, and distance between the applied nano particles. These fixed colours remain constant, even if viewed from different angles.

Paul Smith, Acsys, Modern Coin Design: New Perspectives and Reflections

Paul Smith, on the other hand, the last speaker of the day, demonstrated how various optical effects could be created with the help of a detailed parameter matrix. Using a grid consisting of hexagons, which in turn are each made up of six trapeziums, a laser can manipulate all of the units individually, creating a malleable design that is quickly applicable to a variety of materials.

The long and tiring day was rewarded with a relaxed evening get-together, co-sponsored by Schuler Pressen and Spaleck.