by Ursula Kampmann

translated by Teresa Teklic

February 25, 2014 – On the occasion of the World Money Fair, the 10th Technical Forum took place. What started out small has grown into a major event presenting the minting industry’s significant innovations. As per usual, discussions were moderated with ease by Dieter Merkle and Thomas Hogenkamp, who, despite of the ambitious programme, managed to keep delays at a minimum.

Left to right: Manfred Heller, Dieter Merkle, Barbara Balz and Thomas Hogenkamp. Photo: UK.

They truly deserved the honour paid to them by Manfred Heller and Barbara Balz in the name of the World Money Fair.

A hit at the World Money Fair: The new bicoloured Niobium coin. Photo: Austrian Mint.

DI Dr Manfred Matzinger-Leopold, Director of the Austrian Mint, was the first to speak. He presented the new Niobium coin which has proven highly popular with collectors since the release of its first issue. The 2014 edition is even more special than the other coins in the series. Special metal treatment of the Niobium coin’s inner produces two different colours which nicely bring out the engraved structures.

For obvious reasons, Austrian Mint was reluctant to go into too much detail concerning the new technique. Dr Matzinger-Leopold gave away only this: the minting process of the pieces is complex. First, anodic treatment creates the base colour. Then, the coins are preliminary struck and receive a complicated secondary treatment by a technical partner of Austrian Mint. Lastly, final minting achieves the bicoloured effect.

The new technique is available for B2B clients of Austrian Mint.

New bimetallic coin with polymer interlayer. Photo: UK.

The Bavarian State Mint developed a product that is at least as innovative. The product is as safe for the use in vending machines as it is in hand to hand circulation. “THE COIN”, as Dr Peter Huber and Günther Waadt call their prototype, is an advanced innovation in the line of bimetallic coins, which connects inner and outer with a technical polymer. This polymer can be minted, too, and thus provides an additional security feature. It can be designed in a way that originals can be distinguished from forgeries if viewed in UV light. Thanks to these new security features coins will become as safe as bank notes. This provides the possibility to cover even higher denominations with coins and shift the boundary between coins and bank notes upwards.

Due to its extreme durability, the new polymer does not reduce the coins’ long life span.

The vending industry was also involved in the development of the new coins and confirms that they will not present any problems to already existing vending machines. Even the Deutsche Bundesbank (German Federal Bank) has expressed their support of the technical innovation. We are curious to find out when the first coin series with integrated polymer will be on the market.

Dr Prabir De presents products by the Royal Australian Mint. Photo: UK.

In his talk, Dr Prabir De presented last year’s issues from the Royal Australian Mint, paying special attention to the concave/convex commemorative coins “Southern Cross – Crux”. They were struck with a bent die and polishing required an enormous effort. Polishing took 5 to 6 hours, almost twice as long as usual. Dr Prabir De stressed how crucial the die position was in the minting process and added that the effort was worth it as the Southern Cross had become a very popular collector’s coin in Australia.

Dr Sebastian Zaum from Helmut Fischer GmbH, Institut für Elektrotechnik und Messtechnik, introduced the latest developments in automatic testing methods for gold products. In the last few months, there had been several reports on gold bars that hid a core of tungsten. While traditional testing methods fail to detect this type of forgery, Dr Sebastian Zaum revealed new ways of assessing the inside of such bullions.

Up until now, most machines used to detect forgeries employ X-ray fluorescence analysis to determine the object’s surface material. In order to look deeper into the object the electrical conductivity needs to be tested. This serves to determine the gold content up to a depth of 18 mm. However, as some metal alloys possess the same conductivity as gold, Dr Zaum suggests additionally checking the gold bars density in order to be sure they are pure gold.

Test results of the work group: Euro cent with traditional treatment (left) and Euro cent after many days in circulation, still shiny due to a special coating (right).

Karin Geukes from Spaleck – who, by the way, got along perfectly fine in the midst of an all-male round – suggested a solution to a common problem encountered in mints. The problem are copper surface planchets. These planchets leave the factory in perfect condition but arrive at the mints darkened and with small spots. A team joining experts from Amera, the Bavarian State Mint, the Coinstitute and Spaleck tackled this problem and is now ready to present a solution. The spots are the result of a kind of macro-moistness, i.e. of small water drops which collect on the surface and cannot be eliminated by traditional drying methods. A new drying method designed to prevent this undesirable colouring is to consist of two steps: first, macro-moistness is eliminated by a textile dryer. In a second step, micro-moistness is taken care of by a traditional dryer.

Besides, the working group has developed a substance which prevents darkening of the coins. However, the coat is destroyed during the minting process so that the substance will have to be applied after the planchets have been dried and again after they have been minted.

All interpreting services at the Technical Forum were sponsored by Heimerle & Meule. Photo: UK.

After Heimerle & Meule, who sponsored the translation service at the Technical Forum, had introduced themselves and their expertise on the production of heavy planchets, Börje Olsson and Scott Kuperus gave a talk on a project in cooperation of ScanCoin and the Royal Mint.

The project focuses on EMS (=Electro Magnetic Signature) on coins, which plays a central role in the usage at vending machines. Its EMS decides whether a coin is accepted or rejected. The speakers were interested in the question in how far the wear of plated coins influences their EMS. After all, wear diminishes the thickness of the plating. They found that material and thickness of the plating are crucial. Final results are not existing yet, but the question was raised how to withdraw coins from circulation whose EMS has changed due to wear.

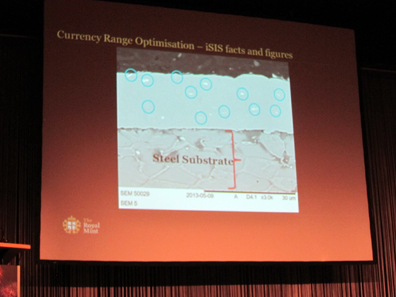

iSIS. An innovation from the Royal Mint. Photo: UK.

Afterwards, Stuart Wilson from the Royal Mint presented a new security feature for the production of plated coins. He introduced an innovative element called iSIS which can be integrated into the alloy used for plating. iSIS contains small particles which distribute themselves evenly in the plated layer and which can be stimulated from the outside in order to set free energy. As this energy can be captured by an optical detector, alloys mixed with iSIS can easily be distinguished from those not mixed with iSIS. This development is another step towards more coin security.

The golden Maple Leaf with its new security feature, the DNA. Photo: Royal Canadian Mint.

The Royal Canadian Mint updated one of their security features, the so-called DNA (Digital Non-Destructive Activation). It takes a “finger print” of each coin, scans it and stores it in an enormous data base. The data base is accessible for certain coin traders who cooperate with the Royal Canadian Mint. This system enables collectors to directly check the authenticity of acquired coins at their coin dealers.

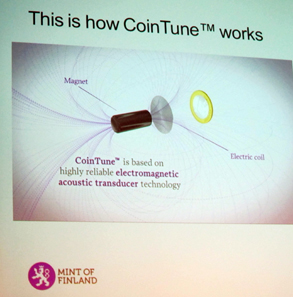

The principle of CoinTune (TM). Photo: UK.

Finland, too, has come up with another security feature which can be integrated into the minting process of circulation coins: CoinTune, which was presented to the professional public in 2013. Matti Rastas, Vice President New Business Development at Mint of Finland, talked about a pilot project which added the new security feature to some 200,000 2-Euro coins. This project was realised at a very low cost during the rimming process. The new pieces had been tested. They conformed to the criteria so far required by the vending industry. Minting had been cost-effective and unproblematic and the new coins were as safe as bank notes, thus another possible way of pushing the border of coin denominations upwards.

An effective tool for designing coin images on the computer. Photo: UK.

The last contribution to the second session came from Robert Newman and Timothy Buch from Delcam PLC: Artcam. Trying to put into words the new possibilities offered by the programme in the three-dimensional designing of dies would be a fruitless endeavour. A short film shown by the presenters demonstrated the incredible new possibilities in terms of three-dimensionality. It starts with the option to bend the pedals of a flower without changing any of its other features and ends with a friendly smile given to an already finished portrait without the slightest alteration in the facial details. Further, the programme offers two tools for generating latent images. There is also a guilloche tool, i.e. a tool for creating the intricate, ornamental lines known from bank notes on coins and, if necessary, to add a microtext to the lines with the microtext-tool. No wonder the question came up whether it would be possible to transfer the images created on the computer to the coins at all. But the software developers were optimistic: they stated that they had already been running tests with their partners.

In times where data security is a much discussed issue, Robert Newman and Timothy Buck did think of ways to prevent the files from falling into the wrong hands. So it is generally impossible to open the files out of office. Only a single person possesses the key required for clearance.

Paul Smith from ACSYS Lasertechnik looked at three different lasers in order to compare their advantages and disadvantages. The lasers under examination were the fiber laser, the UV laser and the picosecond laser. As expected, the most expensive model, the picosecond laser, was also the fastest and best laser. The picosecond laser needs only 2 hours for a task that takes the fiber laser 17 hours. And although it is technically possible to produce a rainbow effect using the fiber laser, this highly complicated procedure is best executed by the picosecond laser.

A problem that many mints face was tackled by Brian Hilliker from FOBA and Dr. Xianyoa Li from the Royal Canadian Mint: since 2011, the Royal Canadian Mint’s product range has tripled and sales have seen a steep increase. Consequently, the mint also needs to produce more dies. The Royal Canadian Mint solved this problem without increasing the number of staff by using a laser for the polishing. That way, the mint can produce 250 dies instead of the previous 50 dies in the same time and without additional staff. The laser executes eight different frosting techniques. Dies which are used for proof coins can be produced purely by laser technique and without any manual labour. This procedure saves an enormous amount of time in the production process. While previously ca 1,440 minutes (= 24 hours or 3 working days) were needed for a coin with a diameter of about 65mm and a detailed depiction, it now takes the laser only 45 minutes (!). For a coin with a diameter of 34mm – that corresponds to a human working time of about 720 minutes (= 12 hours) – it takes as little as 15 minutes. More than anything, the speakers praised the consistent quality secured by the machine as well as its extreme precision and the automatic finish.

Andreas Wächter and Markus Schlein talked about the Servo-Direct-Drive-Technology of their new presses. They were able to compare a traditional Sack & Kiesselbach press with a second press that had the new technology at a mint. They found that it saves two thirds of the energy due to its controlled and thus more precise flow of oil. They also found that the new technology yields more precise results, reduces noise, loss of power and the heating up of the oil.

Martin Stahlschmidt from Gräbener. In the background: the discussion panel. Photo: UK.

Another new press from the GMP series was presented by Martin Stahlschmidt from Gräbener. The series is specially designed for minting collector’s coins and medals. You can access more detailed information on Gräbener’s website.

Eric Sanquer from Proditec. Photo: UK.

The company Proditec introduced a new machine that had been developed in cooperation with a customer. The device serves to analyse coins circulated in cash-centres in order to determine whether they are still suitable for further circulation. Not only can the machine decide whether pieces are still serviceable or not, but it can also check if pieces are soiled and if inscriptions are still decipherable. Moreover, damages to the metal are registered and the compatibility of the pieces with vending machines can be assessed.

Proditec has every reason to be proud as they managed to complete the new examination device specially ordered by the client in only three months.

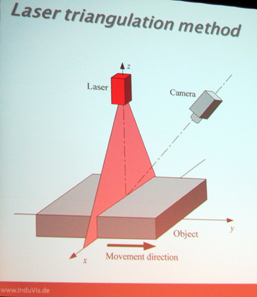

Three-dimensional surface control. Photo: UK.

Last to go was Lutz Büker, who introduced “his” elephant. The elephant turned out to be a high-speed sorting-machine for planchets and coins which relies on 3D technology. It recognises the exact depth of damages on planchets and can thus automatically decide whether the depth is still acceptable and will be evened out by minting. The technology reduces rejections by 0.5%. The machine can recognise bubbles at coin edges and eliminate damages to the edges. In addition, it can be used to make sure dies conform to all features of the master die and conveniently, the machine can be integrated into a packing machine.

After the day’s information overload, we really deserved the leisurely evening that Spaleck and Schuler Pressen had jointly invited to. After all, the reason why people attend such events is often not the actual presentation of new products but the informal conversations about new developments over dinner afterwards…

CoinWeek has filmed most of the presentations of the Technical Forum. If you want to get more information on a special presentation, just watch the speaker talk.